A tensile umbrella manufacturer in India, since nature has something along the same lines, we understand how important it is to provide all our customers with customized solutions that fit their needs. We offer customizable tensile umbrella structures in a variety of sizes, shapes, colors, and configurations to fit your personal needs.

We will never stop until you get what you are looking for. Our professional can assist you from the first consultation to the installation to ensure that your design is exactly how you pictured it.

Let Archway Tensile specify, design, and install a premium tensile umbrella structure for your outdoor area and experience the difference. Our versatility is tested, and we challenge one another to be creative and innovative from design to manufacture to safety and maintenance.

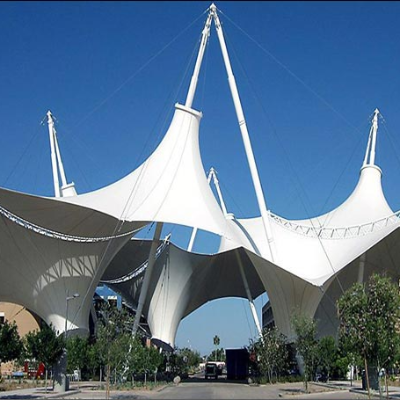

Tensile umbrellas are a structural design made out of tensile materials; they're as much art-filled as scientific engineering. Stretchable umbrellas have also been known for their ability to cover vast areas with only slight reinforcements, offering open airy spaces that are practical and attractive.

They hatched all the engineering details of tensile umbrellas, including the essentials:

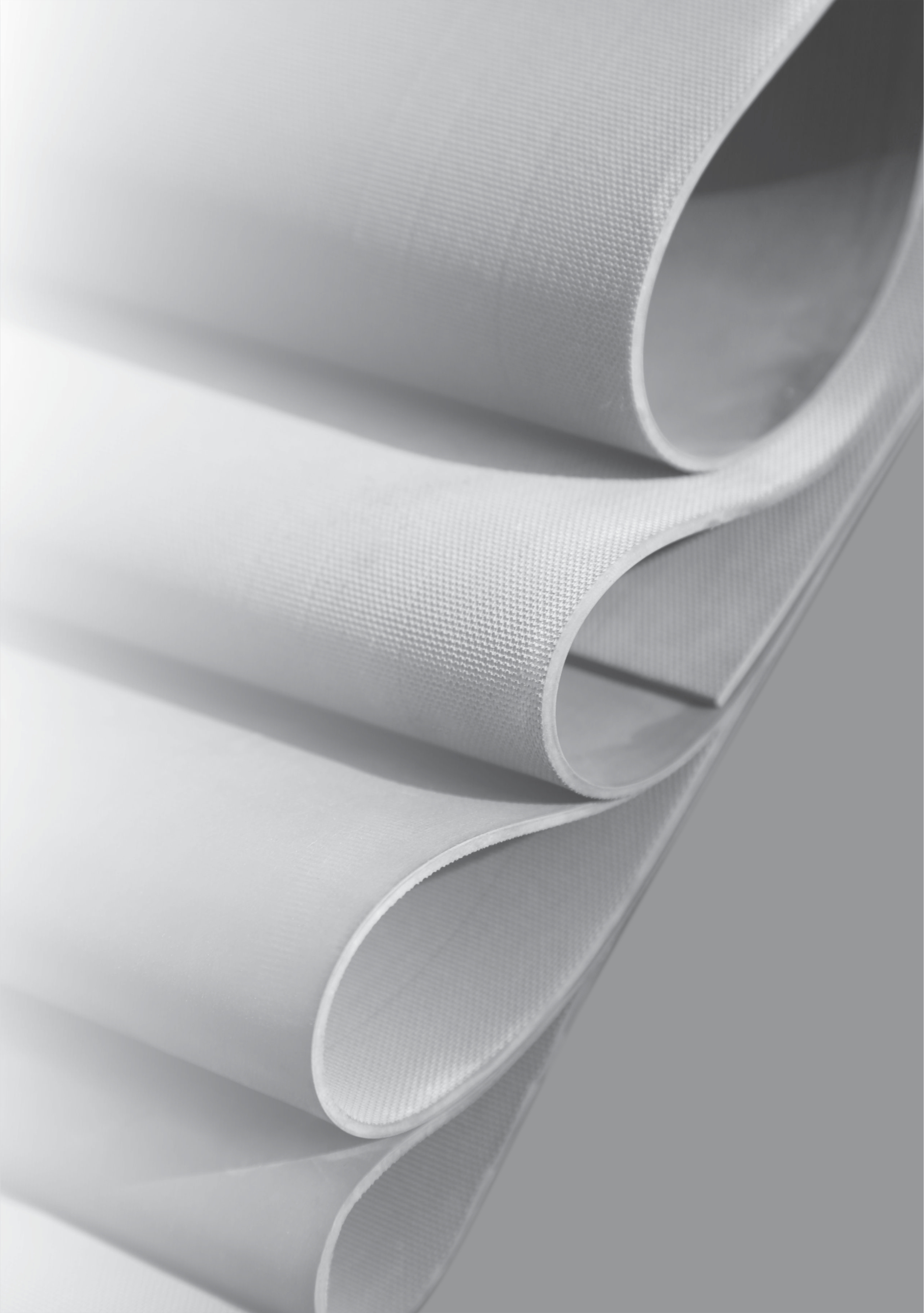

Material: Tensile umbrellas are generally made from weather-resistant high strength material like PVC-covered polyester or PTFE-cover fiberglass. Since they need to hold up against harsh winter weather without losing architectural integrity, these fabrics are picked for being durably stiff yet also flexible.

Support Structure: Tensile umbrellas are supported by a network of tensioned cables or rods that hold up the fabric canopy. This load is transferred onto a dedicated structure consisting of tubes that are designed to carry the forces imposed by the canopy, spread across its entire length.

Anchor anchoring the tensioned cables or rods is important in keeping the tensile umbrella structure stable. These anchor points are usually embedded into concrete foundations or bonded to existing structures to ensure a consistent connection.

Determination of Form Form finding is an essential aspect of tensile structure engineering. That is, to calculate how the fabric canopy should behave when subjected to forces, the shape is not only stable, but also looks good. Advanced computational tools are frequently employed to simulate various load conditions and shape of the tensile umbrella.

Load analysis Engineers analyse the various loads the tensile umbrella structure will face, such as snow, wind and dead load. Knowledge of these loads and their impact to the structure would enable the design of a tensile umbrella that satisfies the safety and performance of the product.

Finite Element Analysis (FEA): In the engineering of tensile structures, a powerful numerical model-based clustering tool that uses software to synthesize the answers of partial differential equations is used to dramatically reduce the amount needed to analyse a structure under various loading or service conditions. Via the creation of a digital twin of the tensile umbrella within a simulation, engineers can model its performance, pinpoint areas of weakness, and then optimize the design for maximum output.

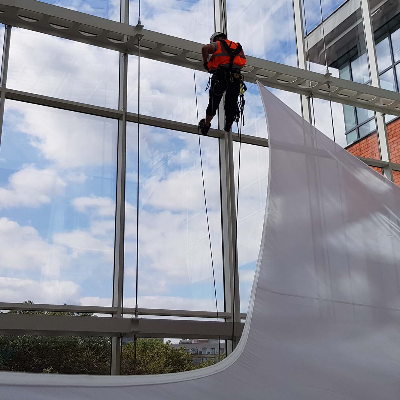

The engineering design of a tensile umbrella requires precise fabrication and expert installation to bring it to life. Each part is assembled with precision by expert technicians, who take care to ensure that each component is fitted together properly and securely, so as to maintain the structural integrity and durability of the tensile umbrella.

Tensile umbrellas are complex engineering marvels that balance form and function, blending innovative design with high-performance materials. Engineers are pushing the limits of tensile structure design using new materials, design techniques, and computational tools to create solutions tailored to a variety of applications.

Car Parking Tensile Structure

Car Parking Tensile Structure Conical Tensile Structure

Conical Tensile Structure Gazebo Tensile Structure

Gazebo Tensile Structure Retractable Tensile Roof

Retractable Tensile Roof Tensile Architecture

Tensile Architecture Tensile Canopy

Tensile Canopy Tensile Canopy Structure

Tensile Canopy Structure Tensile Car Parking

Tensile Car Parking Tensile Car Parking Manufacturer

Tensile Car Parking Manufacturer Tensile Car Parking Shed

Tensile Car Parking Shed Tensile Cloth Shed

Tensile Cloth Shed Tensile Fabric

Tensile Fabric Tensile Fabric Canopy

Tensile Fabric Canopy Tensile Fabric Manufacturer

Tensile Fabric Manufacturer Tensile Fabric Roof

Tensile Fabric Roof  Tensile Fabric Shed

Tensile Fabric Shed Tensile Gazebo

Tensile Gazebo Tensile Membrane Fabric

Tensile Membrane Fabric Tensile Membrane Structure

Tensile Membrane Structure Tensile Parking Shed

Tensile Parking Shed Tensile Roof

Tensile Roof Tensile Roofing

Tensile Roofing Tensile Shade

Tensile Shade Tensile Shed

Tensile Shed Tensile Sheet Roofing

Tensile Sheet Roofing Tensile Structure

Tensile Structure Tensile Structure Car Parking

Tensile Structure Car Parking Tensile Structure Manufacturer

Tensile Structure Manufacturer Tensile Structures in India

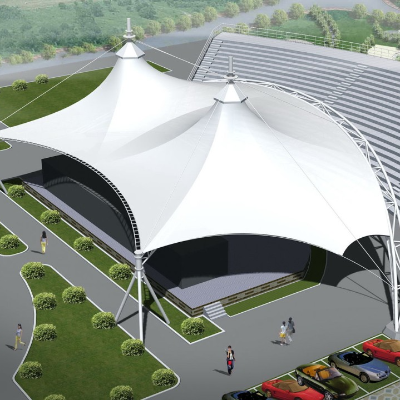

Tensile Structures in India Auditorium Tensile Structure

Auditorium Tensile Structure Entrance Tensile Structure

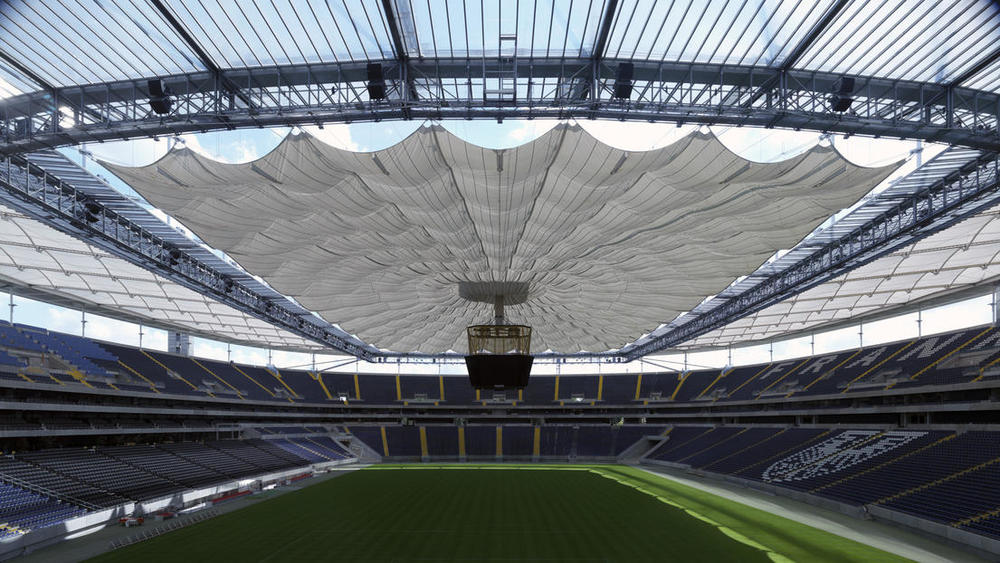

Entrance Tensile Structure Stadium Tensile Structure

Stadium Tensile Structure Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Tensile Car Parking Shade

Tensile Car Parking Shade Tensile food Court Structure

Tensile food Court Structure Tensile Lightweight Structure

Tensile Lightweight Structure Tensile Roof Structure

Tensile Roof Structure Walkway Covering Structure

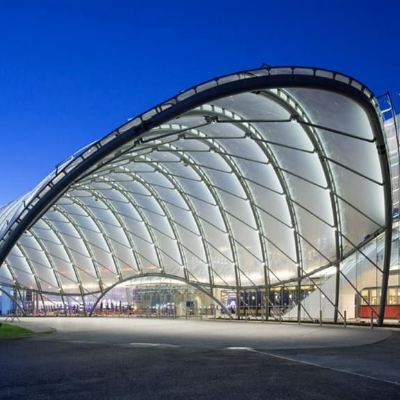

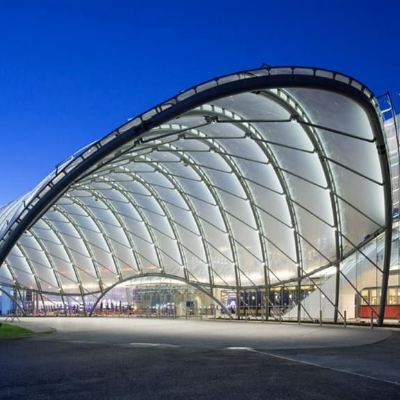

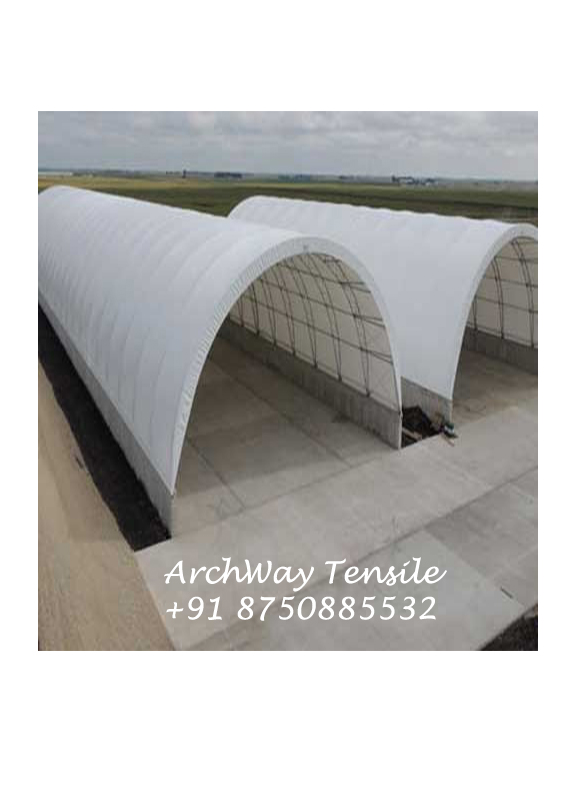

Walkway Covering Structure Arch Supported Tensile Structure

Arch Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Canopy Architecture

Canopy Architecture Canopy Tensile Structure

Canopy Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Car Parking Canopy Structure

Car Parking Canopy Structure Car Parking Structure

Car Parking Structure Car Parking Tensile Shed

Car Parking Tensile Shed Car Parking Tensile Structure Manufacturers

Car Parking Tensile Structure Manufacturers Dome Tensile Structure

Dome Tensile Structure Fabric Structure

Fabric Structure Fabric Tensile Structure

Fabric Tensile Structure Ferrari Fabric Roof

Ferrari Fabric Roof Ferrari Tensile Fabric

Ferrari Tensile Fabric Ferrari Tensile Structure

Ferrari Tensile Structure Hyper Tensile Structure

Hyper Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Linear Tensile Structures

Linear Tensile Structures Mast Supported Tensile Structure

Mast Supported Tensile Structure Mehler Tensile Fabric

Mehler Tensile Fabric Membrane Tensile Structure

Membrane Tensile Structure Modular Tensile Structure

Modular Tensile Structure PTFE Tensile Fabric

PTFE Tensile Fabric PVC Coated Tensile Fabric

PVC Coated Tensile Fabric PVC Tensile Fabric

PVC Tensile Fabric Tensile Car Parking Structure

Tensile Car Parking Structure Tensile Car Porch

Tensile Car Porch Tensile Car Shed

Tensile Car Shed Tensile Ceiling

Tensile Ceiling Tensile Company

Tensile Company Tensile Cone Structure

Tensile Cone Structure Tensile Covering

Tensile Covering Tensile Dome Structure

Tensile Dome Structure Tensile Fabric Car Shed

Tensile Fabric Car Shed Tensile Fabric Clothing

Tensile Fabric Clothing Tensile Fabric Company

Tensile Fabric Company Tensile Fabric Covering

Tensile Fabric Covering Tensile Fabric Facade

Tensile Fabric Facade Tensile Fabric Gazebo

Tensile Fabric Gazebo Tensile Fabric India

Tensile Fabric India Tensile Fabric Installation

Tensile Fabric Installation Tensile Fabric Roof Installation

Tensile Fabric Roof Installation Tensile Fabric Roofing

Tensile Fabric Roofing Tensile Fabric Roofs

Tensile Fabric Roofs Tensile Fabric Shade

Tensile Fabric Shade Tensile Fabric Shade Structure

Tensile Fabric Shade Structure Tensile Fabric Sheet

Tensile Fabric Sheet Tensile Fabric Structure Manufacturer

Tensile Fabric Structure Manufacturer Tensile Fabric Structure

Tensile Fabric Structure Tensile Fabric Supplier

Tensile Fabric Supplier Tensile Fabrication

Tensile Fabrication Tensile Manufacturer

Tensile Manufacturer Tensile Membrane

Tensile Membrane Tensile Membrane Roof

Tensile Membrane Roof Tensile Parking

Tensile Parking Tensile Parking Structure

Tensile Parking Structure Tensile Pergola

Tensile Pergola Tensile Roof Fabric

Tensile Roof Fabric Tensile Roof Installation

Tensile Roof Installation Tensile Roofing Structure

Tensile Roofing Structure Tensile Shade Structure

Tensile Shade Structure Tensile Sheet Shed

Tensile Sheet Shed Tensile Steel Structure

Tensile Steel Structure Tensile Structure Canopy

Tensile Structure Canopy Tensile Structure Company

Tensile Structure Company Tensile Structure Fabric

Tensile Structure Fabric Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Restaurant

Tensile Structure for Restaurant Tensile Structure Installation

Tensile Structure Installation Tensile Structure Parking

Tensile Structure Parking Tensile Structure Roof

Tensile Structure Roof Tensile Structures Architecture

Tensile Structures Architecture Tensile Tent Structures

Tensile Tent Structures Tensile Umbrella Structures

Tensile Umbrella Structures Tensile Work

Tensile Work Tension Structure

Tension Structure Transparent Tensile Fabric

Transparent Tensile Fabric Umbrella Tensile Structure

Umbrella Tensile Structure Walkway Tensile Structure

Walkway Tensile Structure Waterproof Tensile Fabric

Waterproof Tensile Fabric Cafeteria Canopy Tensile Structure

Cafeteria Canopy Tensile Structure