Archway Tensile, the premier destination for innovative and cutting-edge tensile structures in India. As a leading tensile structure manufacturer, we pride ourselves on our commitment to quality, design excellence, and customer satisfaction. With a rich legacy of creating iconic structures that redefine spaces and elevate experiences, we stand at the forefront of the architectural revolution in India.

Archway Tensile is more than just a manufacturer; we are architects of possibility, sculptors of imagination, and visionaries of the extraordinary. Our team of skilled professionals combines technical expertise with artistic flair to bring your wildest architectural dreams to life. From concept to creation, we meticulously craft each structure with precision and passion, ensuring that every detail is perfect.

As one of the top tensile structure manufacturers in India, we offer a diverse range of products and services tailored to meet the unique needs of our clients. Whether you are looking for a stunning canopy to enhance your outdoor space, a striking facade to make a bold statement, or a functional roofing solution for your commercial or residential project, we have the expertise and resources to deliver beyond your expectations.

At Archway Tensile, we believe that form should always follow function. Our structures are not just aesthetically pleasing; they are also designed to withstand the test of time and nature. Using the latest materials and technology, we ensure that our tensile structures are durable, weather-resistant, and environmentally friendly. With us, you can rest assured that your investment is not just a work of art but also a practical and sustainable solution.

What sets us apart from other tensile structure manufacturers in India is our unwavering commitment to excellence and innovation. We constantly push the boundaries of design and engineering to create structures that are not only beautiful but also functional and safe. Our dedication to research and development ensures that we stay ahead of the curve and continue to deliver state-of-the-art solutions that set new industry standards.

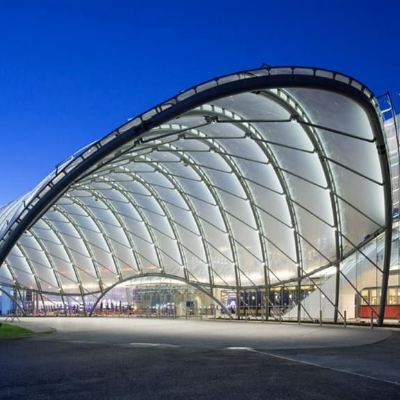

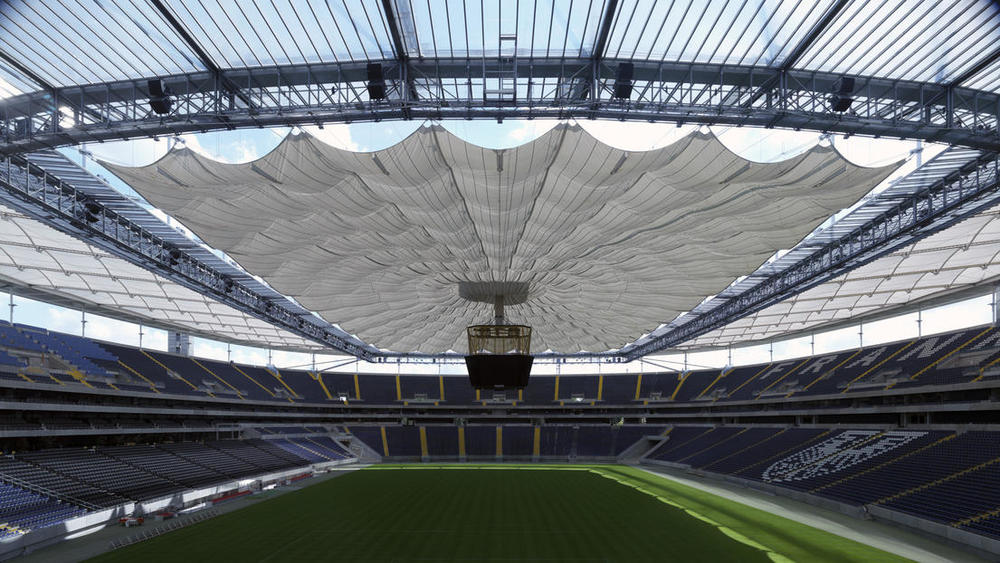

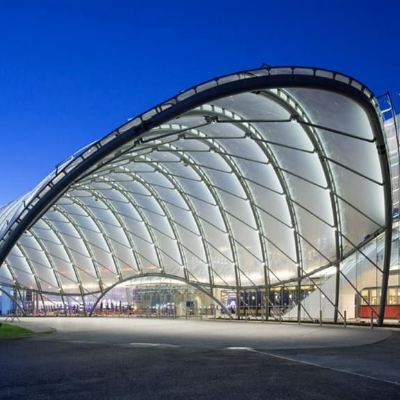

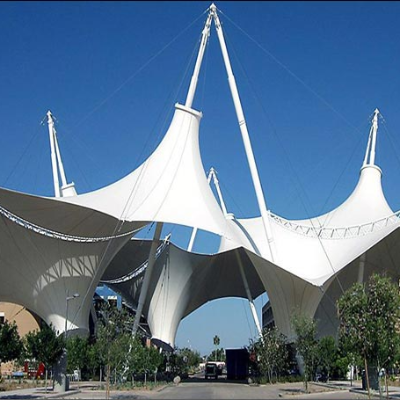

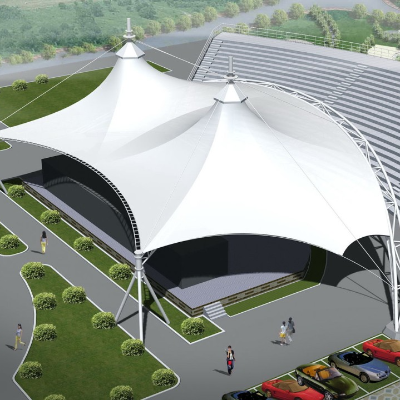

As pioneers in the field of tensile structures, we take pride in our ability to transform spaces and inspire emotions. Whether it's a sleek stadium roof that captures the essence of modernity, a whimsical walkway that invites exploration, or a majestic pavilion that exudes grandeur, our creations leave a lasting impression on all who encounter them. With Archway Tensile, you are not just getting a structure; you are getting a work of art that tells a story and evokes a feeling.

When you choose Archway Tensile as your tensile structure manufacturer in India, you are choosing excellence, innovation, and unparalleled quality. Our commitment to customer satisfaction drives everything we do, from the initial consultation to the final installation. We work closely with you every step of the way to ensure that your vision is realized to perfection.

Archway Tensile is more than just a manufacturer of tensile structures; we are creators of experiences, shapers of landscapes, and architects of the future. Join us on this journey of imagination and discovery, and let us help you bring your architectural dreams to life. Choose Archway Tensile, where innovation meets inspiration, and excellence knows no bounds.

Tensile structures come in various shapes and forms, each offering unique aesthetic appeal and functional benefits. Some common shapes of tensile structures include:

1. Conical: Conical tensile structures feature a cone-like shape, often used for canopies and smaller installations.

2. Hyperbolic Paraboloid: These structures have a doubly-curved shape, creating an elegant and modern look. They are versatile and can be used for roofs, canopies, and more.

3. Saddle: Saddle-shaped tensile structures resemble a saddle, with a curved surface supported by tensioned cables. They are commonly used for roofs and canopies.

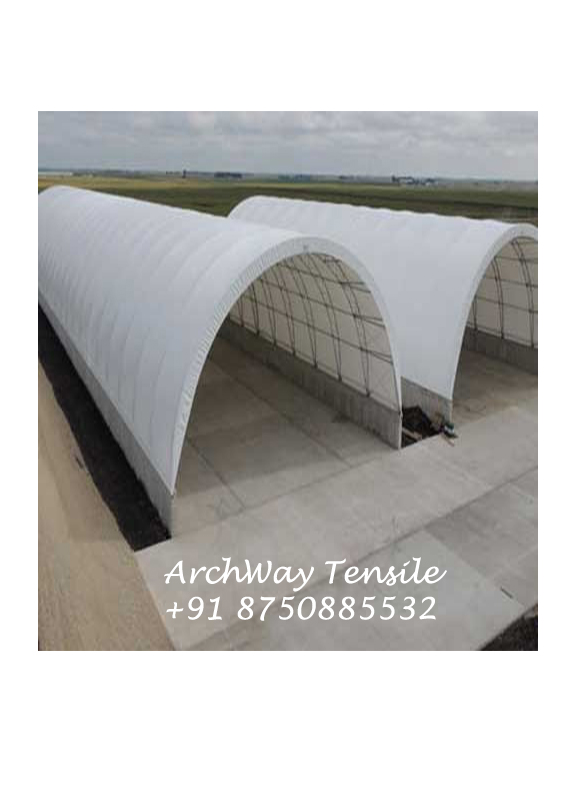

4. Barrel Vault: Barrel vault structures have a curved, elongated shape resembling a barrel. They are ideal for creating long-span roofs and walkways.

5. Cone: Cone-shaped tensile structures feature a conical shape, offering a visually striking design for various architectural applications.

6. Hyper: Also known as hyperbolic paraboloid structures, these have a unique doubly-curved shape that can be used for roofs, canopies, and architectural accents.

The architecture and engineering behind tensile structures manufacturing in India involve a combination of advanced techniques and principles to ensure durability, safety, and aesthetic appeal. Here are some key aspects of the architecture and engineering involved in manufacturing tensile structures in India:

1. Design and Analysis: Tensile structures require meticulous design and engineering analysis to determine the optimal form, material selection, and structural integrity. Advanced software and simulation tools are used to model and analyze the behavior of the structure under various conditions.

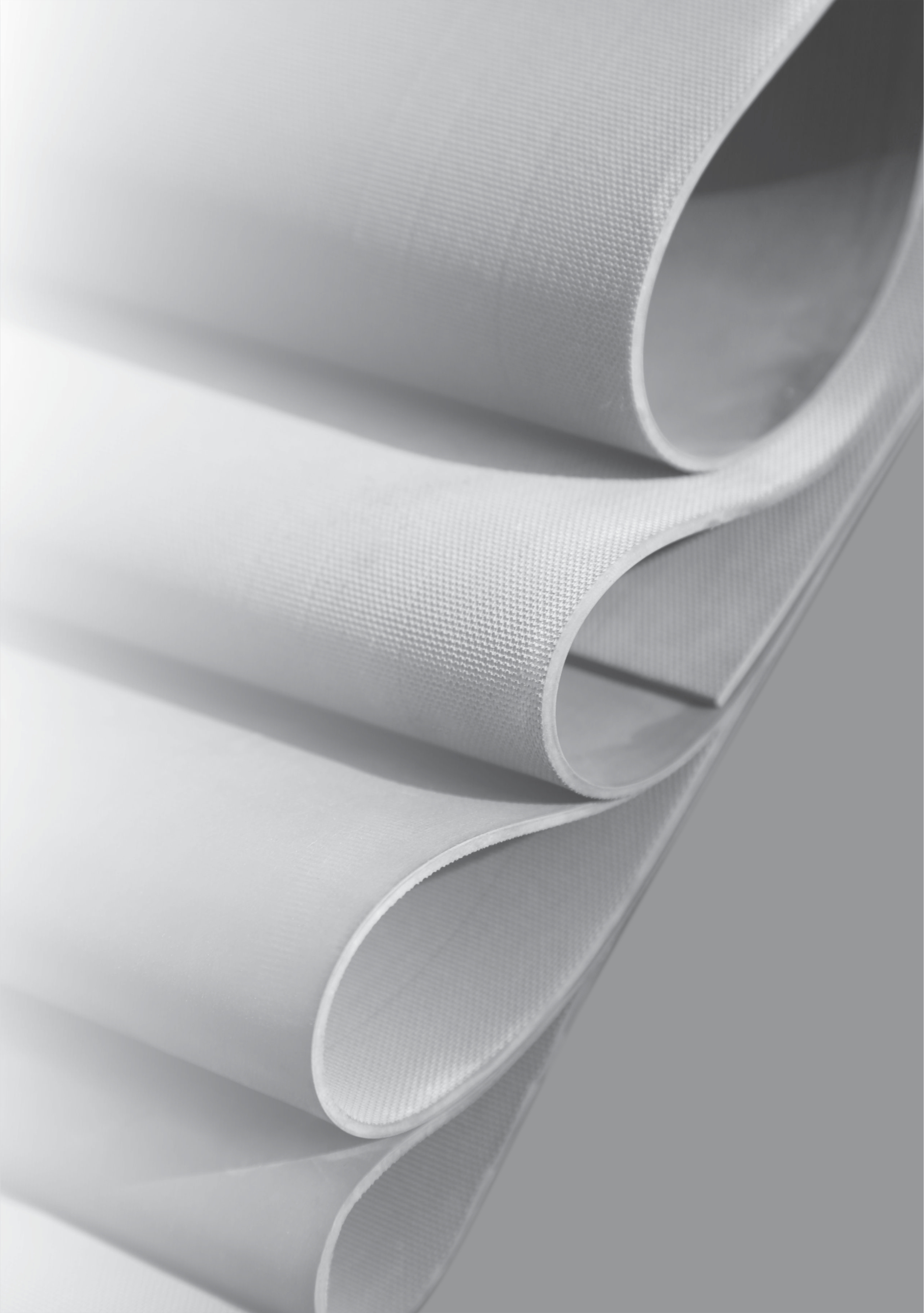

2. Material Selection: The selection of high-quality materials such as PVC-coated polyester fabric, PTFE-coated fiberglass, or ETFE (ethylene tetrafluoroethylene) plays a crucial role in the manufacturing of tensile structures. These materials are chosen for their durability, flexibility, and weather resistance.

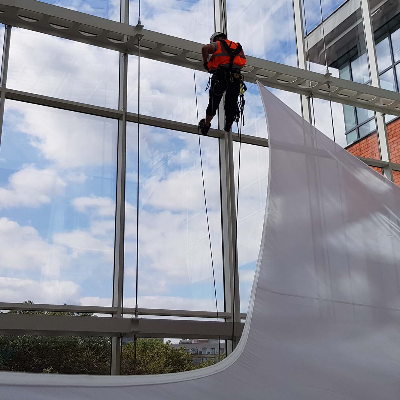

3. Fabrication Techniques: Tensile structures are typically fabricated using a combination of welding, sewing, and tensioning techniques. Precision is key in ensuring that the fabric is tensioned correctly to achieve the desired shape and structural stability.

4. Support System: The support system of tensile structures includes a network of cables, masts, and anchors that work together to provide stability and distribute loads effectively. The engineering of this support system is critical to ensuring the structural integrity of the tensile structure.

5. Installation and Maintenance: Tensile structures require expert installation to ensure proper tensioning and alignment. Regular maintenance is also essential to preserve the structural integrity and longevity of the installation.

Overall, the architecture and engineering behind tensile structures manufacturing in India involve a blend of creativity, technology, and expertise to create structures that are not only visually stunning but also functional, durable, and safe.

Car Parking Tensile Structure

Car Parking Tensile Structure Conical Tensile Structure

Conical Tensile Structure Gazebo Tensile Structure

Gazebo Tensile Structure Retractable Tensile Roof

Retractable Tensile Roof Tensile Architecture

Tensile Architecture Tensile Canopy

Tensile Canopy Tensile Canopy Structure

Tensile Canopy Structure Tensile Car Parking

Tensile Car Parking Tensile Car Parking Manufacturer

Tensile Car Parking Manufacturer Tensile Car Parking Shed

Tensile Car Parking Shed Tensile Cloth Shed

Tensile Cloth Shed Tensile Fabric

Tensile Fabric Tensile Fabric Canopy

Tensile Fabric Canopy Tensile Fabric Manufacturer

Tensile Fabric Manufacturer Tensile Fabric Roof

Tensile Fabric Roof  Tensile Fabric Shed

Tensile Fabric Shed Tensile Gazebo

Tensile Gazebo Tensile Membrane Fabric

Tensile Membrane Fabric Tensile Membrane Structure

Tensile Membrane Structure Tensile Parking Shed

Tensile Parking Shed Tensile Roof

Tensile Roof Tensile Roofing

Tensile Roofing Tensile Shade

Tensile Shade Tensile Shed

Tensile Shed Tensile Sheet Roofing

Tensile Sheet Roofing Tensile Structure

Tensile Structure Tensile Structure Car Parking

Tensile Structure Car Parking Tensile Structures in India

Tensile Structures in India Tensile Umbrella

Tensile Umbrella Auditorium Tensile Structure

Auditorium Tensile Structure Entrance Tensile Structure

Entrance Tensile Structure Stadium Tensile Structure

Stadium Tensile Structure Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Tensile Car Parking Shade

Tensile Car Parking Shade Tensile food Court Structure

Tensile food Court Structure Tensile Lightweight Structure

Tensile Lightweight Structure Tensile Roof Structure

Tensile Roof Structure Walkway Covering Structure

Walkway Covering Structure Arch Supported Tensile Structure

Arch Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Canopy Architecture

Canopy Architecture Canopy Tensile Structure

Canopy Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Car Parking Canopy Structure

Car Parking Canopy Structure Car Parking Structure

Car Parking Structure Car Parking Tensile Shed

Car Parking Tensile Shed Car Parking Tensile Structure Manufacturers

Car Parking Tensile Structure Manufacturers Dome Tensile Structure

Dome Tensile Structure Fabric Structure

Fabric Structure Fabric Tensile Structure

Fabric Tensile Structure Ferrari Fabric Roof

Ferrari Fabric Roof Ferrari Tensile Fabric

Ferrari Tensile Fabric Ferrari Tensile Structure

Ferrari Tensile Structure Hyper Tensile Structure

Hyper Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Linear Tensile Structures

Linear Tensile Structures Mast Supported Tensile Structure

Mast Supported Tensile Structure Mehler Tensile Fabric

Mehler Tensile Fabric Membrane Tensile Structure

Membrane Tensile Structure Modular Tensile Structure

Modular Tensile Structure PTFE Tensile Fabric

PTFE Tensile Fabric PVC Coated Tensile Fabric

PVC Coated Tensile Fabric PVC Tensile Fabric

PVC Tensile Fabric Tensile Car Parking Structure

Tensile Car Parking Structure Tensile Car Porch

Tensile Car Porch Tensile Car Shed

Tensile Car Shed Tensile Ceiling

Tensile Ceiling Tensile Company

Tensile Company Tensile Cone Structure

Tensile Cone Structure Tensile Covering

Tensile Covering Tensile Dome Structure

Tensile Dome Structure Tensile Fabric Car Shed

Tensile Fabric Car Shed Tensile Fabric Clothing

Tensile Fabric Clothing Tensile Fabric Company

Tensile Fabric Company Tensile Fabric Covering

Tensile Fabric Covering Tensile Fabric Facade

Tensile Fabric Facade Tensile Fabric Gazebo

Tensile Fabric Gazebo Tensile Fabric India

Tensile Fabric India Tensile Fabric Installation

Tensile Fabric Installation Tensile Fabric Roof Installation

Tensile Fabric Roof Installation Tensile Fabric Roofing

Tensile Fabric Roofing Tensile Fabric Roofs

Tensile Fabric Roofs Tensile Fabric Shade

Tensile Fabric Shade Tensile Fabric Shade Structure

Tensile Fabric Shade Structure Tensile Fabric Sheet

Tensile Fabric Sheet Tensile Fabric Structure Manufacturer

Tensile Fabric Structure Manufacturer Tensile Fabric Structure

Tensile Fabric Structure Tensile Fabric Supplier

Tensile Fabric Supplier Tensile Fabrication

Tensile Fabrication Tensile Manufacturer

Tensile Manufacturer Tensile Membrane

Tensile Membrane Tensile Membrane Roof

Tensile Membrane Roof Tensile Parking

Tensile Parking Tensile Parking Structure

Tensile Parking Structure Tensile Pergola

Tensile Pergola Tensile Roof Fabric

Tensile Roof Fabric Tensile Roof Installation

Tensile Roof Installation Tensile Roofing Structure

Tensile Roofing Structure Tensile Shade Structure

Tensile Shade Structure Tensile Sheet Shed

Tensile Sheet Shed Tensile Steel Structure

Tensile Steel Structure Tensile Structure Canopy

Tensile Structure Canopy Tensile Structure Company

Tensile Structure Company Tensile Structure Fabric

Tensile Structure Fabric Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Restaurant

Tensile Structure for Restaurant Tensile Structure Installation

Tensile Structure Installation Tensile Structure Parking

Tensile Structure Parking Tensile Structure Roof

Tensile Structure Roof Tensile Structures Architecture

Tensile Structures Architecture Tensile Tent Structures

Tensile Tent Structures Tensile Umbrella Structures

Tensile Umbrella Structures Tensile Work

Tensile Work Tension Structure

Tension Structure Transparent Tensile Fabric

Transparent Tensile Fabric Umbrella Tensile Structure

Umbrella Tensile Structure Walkway Tensile Structure

Walkway Tensile Structure Waterproof Tensile Fabric

Waterproof Tensile Fabric Cafeteria Canopy Tensile Structure

Cafeteria Canopy Tensile Structure