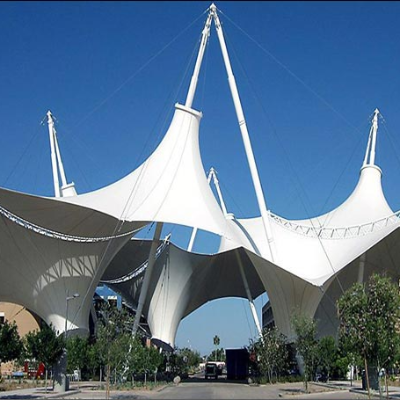

At Archway Tensile we love to recreate architectural glamour with an edge of innovation and ability to design the most amazing 3D conical tensile structures. Being a leading Tensile conical Structure Manufacturer in India, we are committed to quality and we work with our clients every step of the way so that we exceed their expectations.

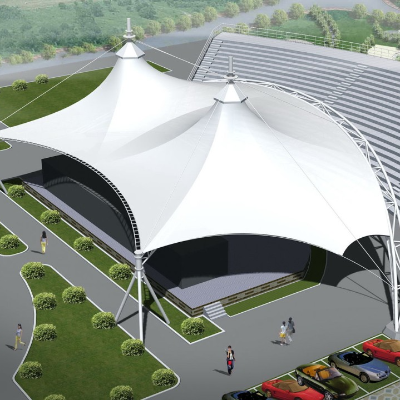

Our bespoke tensile cone structures are a celebration of contemporary design and engineered mastery. These designs which are sectionally manipulated with delicate curves and bold profiles not only provide a shelter but an atmospheric place that arrests the senses. For commercial, residential or public spaces, conical tensile structures provide a fusion of form and function.

One of India's leading pyramid conical tensile structure manufacturers in India. Our Quality As a pyramid tensile structure in India, as per our working policy we can provide detail analysis by obtaining location, ideas, design and budget from the clients We maintain professional relationship and provide the best service to all our clients. Every building is finely crafted with high quality materials and the latest in construction technology to make it robust for a long time. Our talented staff is dedicated to bringing the creative touch of a professional with technical knowledge at your fingertips.

With extensive experience, knowledge in architectural design and ability to penetrate new contracts in the competitive market, we are at the forefront our business known for offering best conical tensile structure India. Our project portfolio is eclectic and a testament to our dedication to innovation and quality. From a simple installation to the most complex architectural project, no job is too big or small.

Why Choose Archway Tensile?

Factory Options: We provide the factory options you need to meet your specific needs.

Quality: All our structures are reviewed for quality performance.

On Time Delivery: We understand the importance of your time; hence we ensure timely delivery of a project.

Satisfied Customers: You're in good hands at Best tensile Conical Structures; our goal is to make sure you are beyond satisfied.

At Archway Tensile, we are committed to exploring new frontiers and furthering what is possible within the architectural world. Not only does our conical tensile fabric structure offer a respite from the elements, it adds an experiential edge to your installation. If you want to embellish a commercial landscape, add appeal to your housing project or set the scene for valuable memorials and other landmarks, our products can be customized across various themes.

Tensile conical fabric structures Celebrating the best in architectural inventiveness and structural engineering. It's the technology and engineering behind these structures that determine its design, functionality and longevity. The architectural technology and engineering details that make conical tensile fabric structures unique are summarized here:

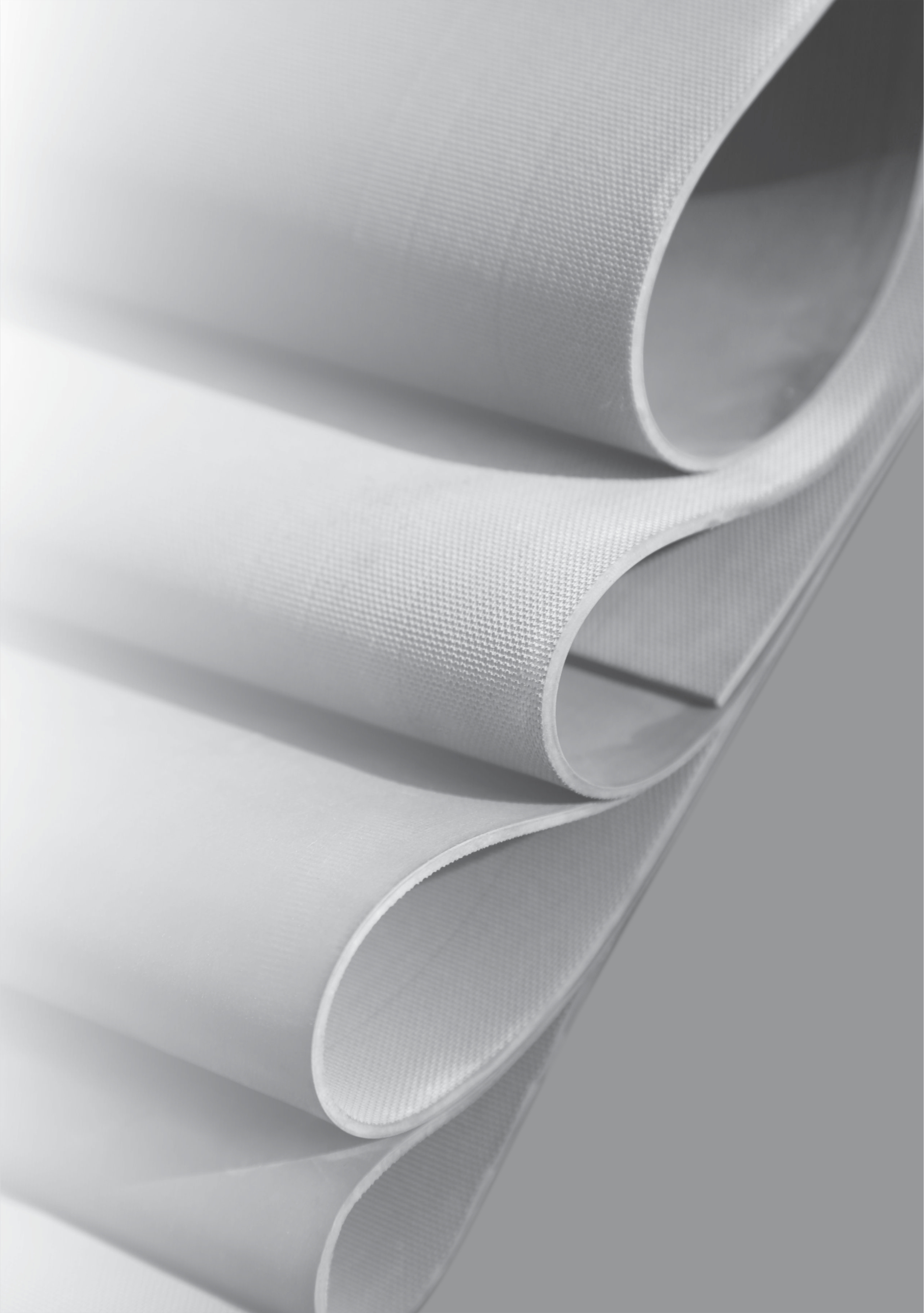

Tensile Fabric Materials:

High Quality Fabrics: Good quality, long life fabrics such as steel or PVC coated polyester, or PTFE coated fiberglass, are the materials commonly used. They are lightweight, flexible and weatherproof which is perfect for draping around curves, making unique bends and creating complex forms.

Structural Design:

Form Finding Process: Special form finding processes develop an optimal shape and tension distribution for the fabric ensuring both, structural safety and aesthetic appearance by engineers.

Wind/Snow Load Analysis: The structural analysis is carried out to verify whether the conical tensile structure can resist loads (wind, snow, etc.) as specified in the codes and standards.

Supporting Structure:

Steel or Aluminum Structure: Heavy duty framework in galvanized steel pipe/aluminum tube makes the tensile fabric structure sturdy and solid enough to withstand high capacity of wind load and snow loading.

Structural Foundations: Custom designed foundations by engineers to be screwed into soil onsite to prevent structure lifting off the ground.

Tensioning Systems:

Cable Systems: Tensioning cables in the fabric membrane layout ensure load spread is equally distributed and help keep conic shape.

Pneumatic: Some conical tensile structures have pneumatic systems which are used to modify the level of tension dynamically with changes in the outdoor conditions.

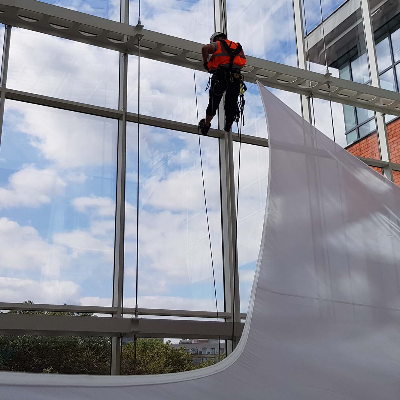

Fabrication and Installation:

Precise Fabrication: The parabolic form of the structure is formed by precision-cutting and welding of fabric panels to achieve continuous, seamless surfaces.

Professional Installation: Trained installation crews install fabric and structure elements on your site, count the pieces meticulously for perfect fit.

Sustainability and Energy Efficiency:

Illumination: Due to the translucency of tensile membrane, natural light is able to penetrate which generally means more energy during the day and an enhanced ability to create beautiful illumination.

Ventilation: Well-designed conical tensile membrane structure encourages natural ventilation system that makes the indoor environmentally pleasant place without depending much on mechanical cooling.

Fabric: If you take care of your fabric by cleaning and checking periodically, it will last longer, as well as your structure staying in good condition.

Life expectancy: At the proposed and installed right conical tensile structure can have a life span long lasting sustainable, cost-efficient architectural solution.

The technology of architectural design and the engineering science that goes into conical tensile fabric structures in India are instrumental in the delivery of such iconic, cutting edge, yet practical architectural wonders on the planet. Utilizing quality materials, computational analysis, and fabrication technology these structures are a pinnacle of architectural achievement today.

Car Parking Tensile Structure

Car Parking Tensile Structure Gazebo Tensile Structure

Gazebo Tensile Structure Retractable Tensile Roof

Retractable Tensile Roof Tensile Architecture

Tensile Architecture Tensile Canopy

Tensile Canopy Tensile Canopy Structure

Tensile Canopy Structure Tensile Car Parking

Tensile Car Parking Tensile Car Parking Manufacturer

Tensile Car Parking Manufacturer Tensile Car Parking Shed

Tensile Car Parking Shed Tensile Cloth Shed

Tensile Cloth Shed Tensile Fabric

Tensile Fabric Tensile Fabric Canopy

Tensile Fabric Canopy Tensile Fabric Manufacturer

Tensile Fabric Manufacturer Tensile Fabric Roof

Tensile Fabric Roof  Tensile Fabric Shed

Tensile Fabric Shed Tensile Gazebo

Tensile Gazebo Tensile Membrane Fabric

Tensile Membrane Fabric Tensile Membrane Structure

Tensile Membrane Structure Tensile Parking Shed

Tensile Parking Shed Tensile Roof

Tensile Roof Tensile Roofing

Tensile Roofing Tensile Shade

Tensile Shade Tensile Shed

Tensile Shed Tensile Sheet Roofing

Tensile Sheet Roofing Tensile Structure

Tensile Structure Tensile Structure Car Parking

Tensile Structure Car Parking Tensile Structure Manufacturer

Tensile Structure Manufacturer Tensile Structures in India

Tensile Structures in India Tensile Umbrella

Tensile Umbrella Auditorium Tensile Structure

Auditorium Tensile Structure Entrance Tensile Structure

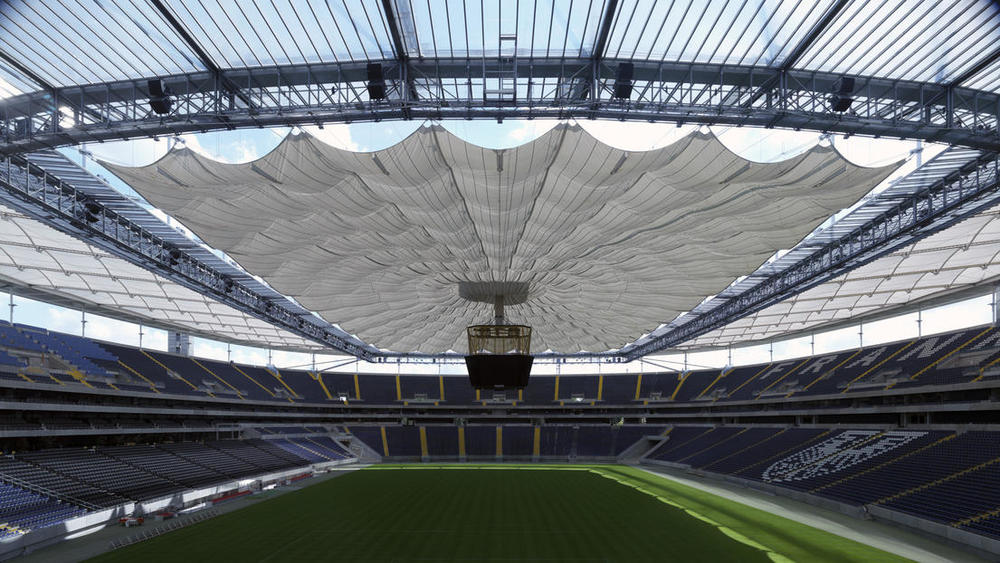

Entrance Tensile Structure Stadium Tensile Structure

Stadium Tensile Structure Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Tensile Car Parking Shade

Tensile Car Parking Shade Tensile food Court Structure

Tensile food Court Structure Tensile Lightweight Structure

Tensile Lightweight Structure Tensile Roof Structure

Tensile Roof Structure Walkway Covering Structure

Walkway Covering Structure Arch Supported Tensile Structure

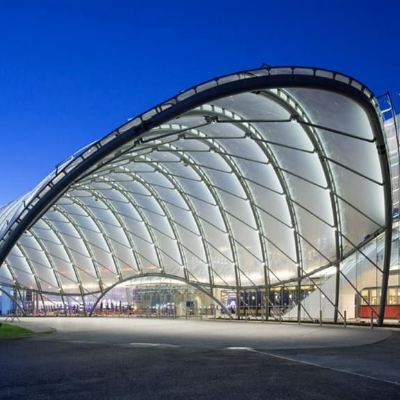

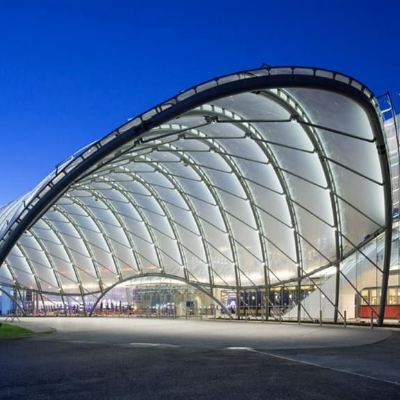

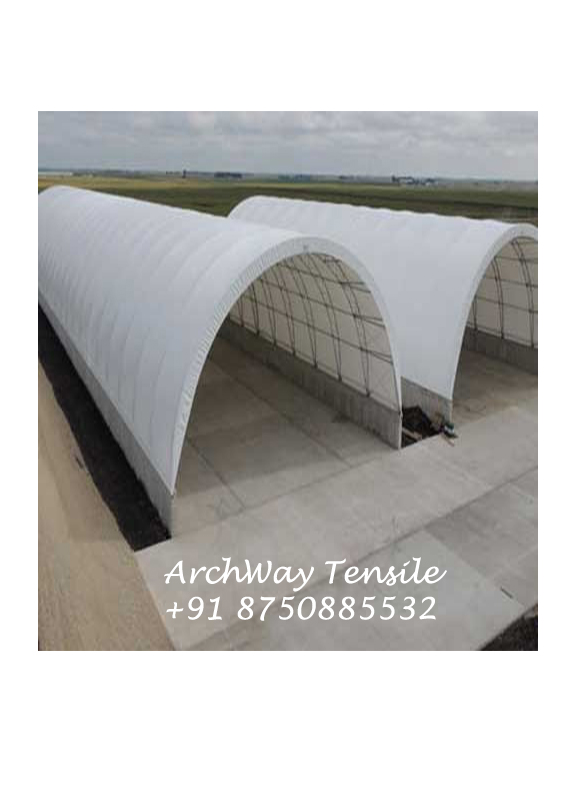

Arch Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Canopy Architecture

Canopy Architecture Canopy Tensile Structure

Canopy Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Car Parking Canopy Structure

Car Parking Canopy Structure Car Parking Structure

Car Parking Structure Car Parking Tensile Shed

Car Parking Tensile Shed Car Parking Tensile Structure Manufacturers

Car Parking Tensile Structure Manufacturers Dome Tensile Structure

Dome Tensile Structure Fabric Structure

Fabric Structure Fabric Tensile Structure

Fabric Tensile Structure Ferrari Fabric Roof

Ferrari Fabric Roof Ferrari Tensile Fabric

Ferrari Tensile Fabric Ferrari Tensile Structure

Ferrari Tensile Structure Hyper Tensile Structure

Hyper Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Linear Tensile Structures

Linear Tensile Structures Mast Supported Tensile Structure

Mast Supported Tensile Structure Mehler Tensile Fabric

Mehler Tensile Fabric Membrane Tensile Structure

Membrane Tensile Structure Modular Tensile Structure

Modular Tensile Structure PTFE Tensile Fabric

PTFE Tensile Fabric PVC Coated Tensile Fabric

PVC Coated Tensile Fabric PVC Tensile Fabric

PVC Tensile Fabric Tensile Car Parking Structure

Tensile Car Parking Structure Tensile Car Porch

Tensile Car Porch Tensile Car Shed

Tensile Car Shed Tensile Ceiling

Tensile Ceiling Tensile Company

Tensile Company Tensile Cone Structure

Tensile Cone Structure Tensile Covering

Tensile Covering Tensile Dome Structure

Tensile Dome Structure Tensile Fabric Car Shed

Tensile Fabric Car Shed Tensile Fabric Clothing

Tensile Fabric Clothing Tensile Fabric Company

Tensile Fabric Company Tensile Fabric Covering

Tensile Fabric Covering Tensile Fabric Facade

Tensile Fabric Facade Tensile Fabric Gazebo

Tensile Fabric Gazebo Tensile Fabric India

Tensile Fabric India Tensile Fabric Installation

Tensile Fabric Installation Tensile Fabric Roof Installation

Tensile Fabric Roof Installation Tensile Fabric Roofing

Tensile Fabric Roofing Tensile Fabric Roofs

Tensile Fabric Roofs Tensile Fabric Shade

Tensile Fabric Shade Tensile Fabric Shade Structure

Tensile Fabric Shade Structure Tensile Fabric Sheet

Tensile Fabric Sheet Tensile Fabric Structure Manufacturer

Tensile Fabric Structure Manufacturer Tensile Fabric Structure

Tensile Fabric Structure Tensile Fabric Supplier

Tensile Fabric Supplier Tensile Fabrication

Tensile Fabrication Tensile Manufacturer

Tensile Manufacturer Tensile Membrane

Tensile Membrane Tensile Membrane Roof

Tensile Membrane Roof Tensile Parking

Tensile Parking Tensile Parking Structure

Tensile Parking Structure Tensile Pergola

Tensile Pergola Tensile Roof Fabric

Tensile Roof Fabric Tensile Roof Installation

Tensile Roof Installation Tensile Roofing Structure

Tensile Roofing Structure Tensile Shade Structure

Tensile Shade Structure Tensile Sheet Shed

Tensile Sheet Shed Tensile Steel Structure

Tensile Steel Structure Tensile Structure Canopy

Tensile Structure Canopy Tensile Structure Company

Tensile Structure Company Tensile Structure Fabric

Tensile Structure Fabric Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Restaurant

Tensile Structure for Restaurant Tensile Structure Installation

Tensile Structure Installation Tensile Structure Parking

Tensile Structure Parking Tensile Structure Roof

Tensile Structure Roof Tensile Structures Architecture

Tensile Structures Architecture Tensile Tent Structures

Tensile Tent Structures Tensile Umbrella Structures

Tensile Umbrella Structures Tensile Work

Tensile Work Tension Structure

Tension Structure Transparent Tensile Fabric

Transparent Tensile Fabric Umbrella Tensile Structure

Umbrella Tensile Structure Walkway Tensile Structure

Walkway Tensile Structure Waterproof Tensile Fabric

Waterproof Tensile Fabric Cafeteria Canopy Tensile Structure

Cafeteria Canopy Tensile Structure